INDEX to the series

A beautiful sub-zero sunny day.

A perfect day to stack all the frozen food outside while I defrost my freezer.

I'll save a bit of energy and reduce future ice buildup by checking the seal and door hinge adjustment. Easy to do.

Also a good time to inventory what I have on hand and check expiry dates/condition. And clean up a bit of raspberry juice.

The ice build up is all on one end of the freezer. I can see a finger of ice reaching up to where the moist room air has been entering the freezer.

Likely the hinge on the left side of the freezer is a bit too high.

[click any pic to enlarge]

The two hinges hide under plastic covers that snap off if pried gently.

Mine has four Philips head screws holding each hinge.

With the door/cover in the down position, I carefully loosen all eight screws about 1 turn counter clockwise. Because the screws are in slots, the cover is free to move up and down slightly. I could lift the cover off completely if I wanted to.

Instead, I lift each corner slightly and press down slightly to ensure that the cover is sitting evenly all the way around.

The hinges hold the cover securely but should not hold it UP or DOWN from its normal level seated closed position.

Now that I have it in that position, I carefully tighten all the screws alternating between the hinges - one screw on one hinge, the same screw on the other hinge, then the next screw on the first hinge etc.

The final step is to check all around the cover with a piece of paper to ensure that the paper is gripped firmly when the cover is closed.

I did this paper seal test before hinge adjustment and it was apparent to me that the paper was not held well on the left end of the cover. It is now.

Another sign of good freezer health is the vacuum that results when the door is freshly closed. When I open and close the cover now it snaps shut and holds tight. The warm room air trapped in the freezer cools and shrinks. Difficult to open for a few minutes! It did not do that before, at least not like it does now! All good.

While empty, I carefully cleaned and disinfected the seal and door. Some slight mold spots were removed.

The freezer is chilling and will be refilled with sorted frozen food in a couple of hours, kept frozen outside.

I will try to "read" the frost buildup over the next few months to see if I have reduced the seal leak.

Thanks for your interest

George Plhak

Lions Head Ontario Canada

Update June 6, 2020

Ice buildup has started around the left hinge but does not seem to be very severe.

At the right side, there is almost no ice.

INDEX to the series

Sunday, March 15, 2020

Thursday, March 12, 2020

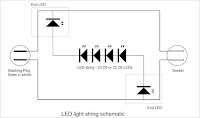

fixing led string lights 2

Addendum to fixing led string lights.

An example of fuses in a string. Two of the tiny 10mm 3A fuses down in a recess in the plug.

[click any pics to enlarge]

I found it helpful to use a small flat screw driver to push open the tiny cover.

Tiny fast blow 3.0 amp 10mm fuses. You can buy them at Amazon in a larger lot for about 50 cents each. Beautiful laser engraved printing on one end cap.

I've had a chance to look carefully at two strings of more recent (2018 manufacture) from the same company. One has 25 C9 bulbs (top) while the other has 35 C6 bulbs (bottom).

There are significant changes in the strings to what I described previously.

I am sorry to say that the LEDs on both newer strings are NOT REPLACEABLE. I highlighted the corrosion that appeared in the ones I looked at earlier. Apparently the manufacturer has done away with "repair-ability".

Fuses protect from overloads if the user, for example, plugs too many strings together in series. Only the C9 string has fuses in the plug, the C6 string does not. The C9 string came with two spare fuses in a small baggy taped to the plug. Two fuses protect both the line and the neutral since the plug and socket are not polarized.

If either of the two fuses is blown (open circuit) the LED string will not light, nor will another string plugged into it at either the end socket or the feed through socket on the back of the plug. Both are fed by the fuses.

The bulb assemblies of both are masterpieces of precision injection molding. These will not come apart without damage. Probably water tight except for the plug and socket.

The same 3 wire arrangement is used on both newer strings. Two conductors go from plug to socket to carry the line circuit to the next string. The LEDs in the string are all in the third line, down the center if you will. At the plug end, the LEDs connect to the fuse side of the line. At the socket end, the LED string connects to the neutral. Actually, the plug and socket are not polarized, so there is no line and neutral in that sense, but there really is!

There is no canister containing extra parts like resistors or blocking diodes in the newer strings.

Except for the two LEDs nearest the ends, all LEDs have two wires out the bottom. All are in a series string. There is no physical indication of polarity (cathode/anode) on the outside of the bulb assembly, so if you are going to be cutting them out of the string, you'd better mark for orientation or be prepared to test for polarity later.

The end LEDs have three wires coming out the bottom. On each, two of the wires are connected together and to one side of the LED. The third wire is to the rest of the string. The C9 bulb string is pictured.

It is worth noting that at each end, it is the center conductor of the 3 wire LED base that goes to the socket or plug.

Thanks for your interest

George Plhak

Lions Head Ontario Canada

This is an addendum to fixing led string lights.

An example of fuses in a string. Two of the tiny 10mm 3A fuses down in a recess in the plug.

[click any pics to enlarge]

I found it helpful to use a small flat screw driver to push open the tiny cover.

Tiny fast blow 3.0 amp 10mm fuses. You can buy them at Amazon in a larger lot for about 50 cents each. Beautiful laser engraved printing on one end cap.

I've had a chance to look carefully at two strings of more recent (2018 manufacture) from the same company. One has 25 C9 bulbs (top) while the other has 35 C6 bulbs (bottom).

There are significant changes in the strings to what I described previously.

I am sorry to say that the LEDs on both newer strings are NOT REPLACEABLE. I highlighted the corrosion that appeared in the ones I looked at earlier. Apparently the manufacturer has done away with "repair-ability".

Fuses protect from overloads if the user, for example, plugs too many strings together in series. Only the C9 string has fuses in the plug, the C6 string does not. The C9 string came with two spare fuses in a small baggy taped to the plug. Two fuses protect both the line and the neutral since the plug and socket are not polarized.

If either of the two fuses is blown (open circuit) the LED string will not light, nor will another string plugged into it at either the end socket or the feed through socket on the back of the plug. Both are fed by the fuses.

The bulb assemblies of both are masterpieces of precision injection molding. These will not come apart without damage. Probably water tight except for the plug and socket.

The same 3 wire arrangement is used on both newer strings. Two conductors go from plug to socket to carry the line circuit to the next string. The LEDs in the string are all in the third line, down the center if you will. At the plug end, the LEDs connect to the fuse side of the line. At the socket end, the LED string connects to the neutral. Actually, the plug and socket are not polarized, so there is no line and neutral in that sense, but there really is!

There is no canister containing extra parts like resistors or blocking diodes in the newer strings.

Except for the two LEDs nearest the ends, all LEDs have two wires out the bottom. All are in a series string. There is no physical indication of polarity (cathode/anode) on the outside of the bulb assembly, so if you are going to be cutting them out of the string, you'd better mark for orientation or be prepared to test for polarity later.

The end LEDs have three wires coming out the bottom. On each, two of the wires are connected together and to one side of the LED. The third wire is to the rest of the string. The C9 bulb string is pictured.

It is worth noting that at each end, it is the center conductor of the 3 wire LED base that goes to the socket or plug.

Thanks for your interest

George Plhak

Lions Head Ontario Canada

This is an addendum to fixing led string lights.

my typical electrical day winter 2

INDEX to the series

Daylight savings time changed this past weekend.

I normally check my hourly electricity usage at my utility's website to make sure I've reset the water heater timer correctly so that my hot water heater does not come on during peak priced periods. The water heater is a big electricity user here that I can see easily on this chart. Since I have kept it off for twelve hours, it takes a big gulp when it comes back on, when it's cheaper after 7pm. Cheaper by half!

[click any pic to enlarge]

As a single person, I don't use a lot of hot water yet I NEVER run out of scalding hot water during the daytime. Even at 6:45pm after twelve hours OFF (graph of actual water temperature below).

Your mileage may vary. I have a relatively new heater which is a huge improvement over the old one. I am only one, relatively frugal person as a hot water user.

On the Hydro One website (pic above) I can see my water heater coming back ON (biggest bar in the green) yesterday, five minutes after the end of On-Peak pricing. I use a cheap but great timer that does the job perfectly. It is somewhat cryptic to set if you only look at it four times a year. The light is not very good and I need to remember a flashlight.

I did it wrong once and made the situation worse with the heater off for six hours (doing the right thing) and then coming back on in the last hour of peak price, costing me twice as much!

Because my water heater is a wired in appliance running 240 volts, I can't use the sort of web enabled timer/monitor that I was using for smaller plug-in appliances, like the Itead Sonoff S31.

Compare with the daytime winter electrical picture of three plus years ago. At the time, I was using my own smart meter reader which had higher resolution so it looks more jagged. The big spikes (marked W) from the water heater were easily seen. I was trying only a few hours of On-Peak inhibit at the time (marked C). I was also inhibiting the refrigerator and the freezer so the house energy draw drops almost to zero during C.

I'd like to get a web enabled wired-in device for the water heater but I'd still have to check four times a year that it is set correctly. My utility rate changes happen twice a year on a different schedule than the daylight time changes. Four changes per year to check.

Water heater inhibit is a big winner for me as far as savings on my electrical bill. I estimate that the new water heater and the inhibit technique save me between 15-20% on my electricity bill. This is possible because I use less electricity and only off-peak for hot water.

Off peak timing is quite different from lowering the thermostat temperature of the water heater which is actually quite dangerous.

I have the tank thermostat set at the recommended 49C so that Legionnaires’ bacteria are minimized. The tank cools about three degrees after twelve hours off. Returns quickly to the set point at 7pm until the next morning.

Sorry if the graph is difficult to read. It is from the top of my water heater tank today and shows the low temp for the day and the rise to set point.

I'd mentioned my ambition to leave the grid entirely during On-Peak in future.

Thank you for your interest.

George Plhak

Lions Head Ontario Canada

INDEX to the series

Daylight savings time changed this past weekend.

I normally check my hourly electricity usage at my utility's website to make sure I've reset the water heater timer correctly so that my hot water heater does not come on during peak priced periods. The water heater is a big electricity user here that I can see easily on this chart. Since I have kept it off for twelve hours, it takes a big gulp when it comes back on, when it's cheaper after 7pm. Cheaper by half!

[click any pic to enlarge]

As a single person, I don't use a lot of hot water yet I NEVER run out of scalding hot water during the daytime. Even at 6:45pm after twelve hours OFF (graph of actual water temperature below).

Your mileage may vary. I have a relatively new heater which is a huge improvement over the old one. I am only one, relatively frugal person as a hot water user.

On the Hydro One website (pic above) I can see my water heater coming back ON (biggest bar in the green) yesterday, five minutes after the end of On-Peak pricing. I use a cheap but great timer that does the job perfectly. It is somewhat cryptic to set if you only look at it four times a year. The light is not very good and I need to remember a flashlight.

I did it wrong once and made the situation worse with the heater off for six hours (doing the right thing) and then coming back on in the last hour of peak price, costing me twice as much!

Because my water heater is a wired in appliance running 240 volts, I can't use the sort of web enabled timer/monitor that I was using for smaller plug-in appliances, like the Itead Sonoff S31.

Compare with the daytime winter electrical picture of three plus years ago. At the time, I was using my own smart meter reader which had higher resolution so it looks more jagged. The big spikes (marked W) from the water heater were easily seen. I was trying only a few hours of On-Peak inhibit at the time (marked C). I was also inhibiting the refrigerator and the freezer so the house energy draw drops almost to zero during C.

I'd like to get a web enabled wired-in device for the water heater but I'd still have to check four times a year that it is set correctly. My utility rate changes happen twice a year on a different schedule than the daylight time changes. Four changes per year to check.

Water heater inhibit is a big winner for me as far as savings on my electrical bill. I estimate that the new water heater and the inhibit technique save me between 15-20% on my electricity bill. This is possible because I use less electricity and only off-peak for hot water.

Off peak timing is quite different from lowering the thermostat temperature of the water heater which is actually quite dangerous.

I have the tank thermostat set at the recommended 49C so that Legionnaires’ bacteria are minimized. The tank cools about three degrees after twelve hours off. Returns quickly to the set point at 7pm until the next morning.

Sorry if the graph is difficult to read. It is from the top of my water heater tank today and shows the low temp for the day and the rise to set point.

I'd mentioned my ambition to leave the grid entirely during On-Peak in future.

Thank you for your interest.

George Plhak

Lions Head Ontario Canada

INDEX to the series

Wednesday, March 11, 2020

battery testing 3

Retesting after 6 months of daily use shows ~10% decline in capacity of my 18650 lithium rechargeable cells.

Last summer I tested three new 2200mAh cells. Initial average capacity was about 2030 mAh with my test which may or may not be accurate. After six months in service, I repeated the test with the same tester and method and found average cell capacity was now about 1822 mAh, or a reduction in capacity of about 10%. Raw data is here.

I attribute the reduction in capacity to my daily usage of the batteries although there could be other causes (* below).

The squiggle (~ tilde) before the 10 means "about" and that is really the theme of this post. Often in amateur science and engineering we need an approximate answer to check a hypothesis or opinion. Some quick measurements, even if approximate, are better than no data at all. Hence the "about". Sometimes repeatability and consistency may be more important than absolute accuracy when we are trying to compare.

In the case of these batteries I had tested for capacity about six months ago. Since then I had used these batteries daily in a vape pipe. They seemed to be performing well. Typically I would switch a battery sometime mid-day putting the partially discharged battery back onto the charger and inserting one of the two other charged batteries into the pipe. So I knew two of the three batteries went through some sort of discharge/charge cycle daily determined by my vaping habit with was pretty steady during the six months. I tried to randomize which battery I did not use each day but wasn't entirely careful about that aspect.

Since I had not used these PKCELL 2200mAh batteries before, I was curious if there was an effect on battery capacity and how much it might be.

Why go to the trouble of testing? I paid about Cdn$15 each for these cells. Some have been junk. I am accumulating things which use 18650 cells and had other applications in mind so I will need to buy more. The best way to determine capacity is to measure with a controlled test.

Initially I had tested each battery three times. Three data points. I like three. With only two measurements, if something goes wrong or varies, it may not be apparent in the data. The two measurements will differ always. With three measurements, hopefully two will be more similar than the one which varied. Ideally all three would cluster tightly. More measurements would be even better but we are after an approximate answer so three is good.

I tested with the same ZHIYU ZB2L3 v2.3a tester and the same 7.5 ohm resistor.

There is a new version 3 of the tester which I have ordered.

[click any pic to enlarge]

I considered changing the load resistor. I am simply using one of the two resistors that came with the kit. Readers will notice that I changed the arrangement of the load for the second round of testing with auto batteries to create a heavier load. I'd like to more closely match the 1C rate that the manufacturer has used for determining the branded 2200mAh rate. But at this point that is less important to me than using the same test and load to compare batteries from different manufacturers or different batches from the same company.

I have recently done initial testing of two new batches of 18650 batteries: four more of the PKCELL 2200mAh and two bright pink Samsung cells, the best I've tested so far! All tests with three repeats each.

Thank you for your interest.

George Plhak

Lions Head, Ontario, Canada

* Other causes - I knew you'd ask. Hypothetical causes really, but possible. Like maybe the batteries have some manufacturing defect that causes them to loose capacity independent of charge/discharge? Or maybe I stored them in a hot car in the sun? I did not, with these batteries, but four similar cells are installed in two emergency flashlights in my cars. Not used at all but subject to some extremes in temperature. I might retest those cells another time.

[The next day] Another possibility why the measurements this time are lower. I had forgotten but was reminded by the photo I used above: I wrote that I was not happy with the battery holder and had ordered a different type. After the new holder arrived, I installed it with shorter, larger gauge wire as you can see in the pic. This is the tester and holder used for this series of tests, on the right.

So it is likely that the resistance of the output load circuit is now less particularly because of the shorter beefier wire. The holder contacts also look more substantial and are well soldered to the wires. Lower load resistance would increase current (the C rate) and reduce mAh measured. Would it be ~10%? I don't know. I should measure! That's the original battery holder and wires to the left.

I won't go back and retest with the thinner wire. But when I retest the latest cells, I will be comparing them to the results from this tester. That's the importance of consistency.

As is my custom, this is not a paid review nor do I receive or solicit any product in return for writing. I am not selling these products. Just ideas. I don't get a commission. I don't show ads. I don't have a fundraising or patreon page.

I write in the hope that this is interesting or useful to you.

If you would like to show support for my independent work,

please consider commenting or buying one of my books? Thank you. George

Last summer I tested three new 2200mAh cells. Initial average capacity was about 2030 mAh with my test which may or may not be accurate. After six months in service, I repeated the test with the same tester and method and found average cell capacity was now about 1822 mAh, or a reduction in capacity of about 10%. Raw data is here.

I attribute the reduction in capacity to my daily usage of the batteries although there could be other causes (* below).

The squiggle (~ tilde) before the 10 means "about" and that is really the theme of this post. Often in amateur science and engineering we need an approximate answer to check a hypothesis or opinion. Some quick measurements, even if approximate, are better than no data at all. Hence the "about". Sometimes repeatability and consistency may be more important than absolute accuracy when we are trying to compare.

In the case of these batteries I had tested for capacity about six months ago. Since then I had used these batteries daily in a vape pipe. They seemed to be performing well. Typically I would switch a battery sometime mid-day putting the partially discharged battery back onto the charger and inserting one of the two other charged batteries into the pipe. So I knew two of the three batteries went through some sort of discharge/charge cycle daily determined by my vaping habit with was pretty steady during the six months. I tried to randomize which battery I did not use each day but wasn't entirely careful about that aspect.

Since I had not used these PKCELL 2200mAh batteries before, I was curious if there was an effect on battery capacity and how much it might be.

Why go to the trouble of testing? I paid about Cdn$15 each for these cells. Some have been junk. I am accumulating things which use 18650 cells and had other applications in mind so I will need to buy more. The best way to determine capacity is to measure with a controlled test.

Initially I had tested each battery three times. Three data points. I like three. With only two measurements, if something goes wrong or varies, it may not be apparent in the data. The two measurements will differ always. With three measurements, hopefully two will be more similar than the one which varied. Ideally all three would cluster tightly. More measurements would be even better but we are after an approximate answer so three is good.

I tested with the same ZHIYU ZB2L3 v2.3a tester and the same 7.5 ohm resistor.

There is a new version 3 of the tester which I have ordered.

[click any pic to enlarge]

I considered changing the load resistor. I am simply using one of the two resistors that came with the kit. Readers will notice that I changed the arrangement of the load for the second round of testing with auto batteries to create a heavier load. I'd like to more closely match the 1C rate that the manufacturer has used for determining the branded 2200mAh rate. But at this point that is less important to me than using the same test and load to compare batteries from different manufacturers or different batches from the same company.

I have recently done initial testing of two new batches of 18650 batteries: four more of the PKCELL 2200mAh and two bright pink Samsung cells, the best I've tested so far! All tests with three repeats each.

Thank you for your interest.

George Plhak

Lions Head, Ontario, Canada

* Other causes - I knew you'd ask. Hypothetical causes really, but possible. Like maybe the batteries have some manufacturing defect that causes them to loose capacity independent of charge/discharge? Or maybe I stored them in a hot car in the sun? I did not, with these batteries, but four similar cells are installed in two emergency flashlights in my cars. Not used at all but subject to some extremes in temperature. I might retest those cells another time.

[The next day] Another possibility why the measurements this time are lower. I had forgotten but was reminded by the photo I used above: I wrote that I was not happy with the battery holder and had ordered a different type. After the new holder arrived, I installed it with shorter, larger gauge wire as you can see in the pic. This is the tester and holder used for this series of tests, on the right.

So it is likely that the resistance of the output load circuit is now less particularly because of the shorter beefier wire. The holder contacts also look more substantial and are well soldered to the wires. Lower load resistance would increase current (the C rate) and reduce mAh measured. Would it be ~10%? I don't know. I should measure! That's the original battery holder and wires to the left.

I won't go back and retest with the thinner wire. But when I retest the latest cells, I will be comparing them to the results from this tester. That's the importance of consistency.

As is my custom, this is not a paid review nor do I receive or solicit any product in return for writing. I am not selling these products. Just ideas. I don't get a commission. I don't show ads. I don't have a fundraising or patreon page.

I write in the hope that this is interesting or useful to you.

If you would like to show support for my independent work,

please consider commenting or buying one of my books? Thank you. George

Friday, February 28, 2020

solar printing

Markus Kayser - Solar Sinter Project from Markus Kayser on Vimeo.

Amazing.

I wonder if finely shredded plastic waste could be used instead of sand to make fused plastic works?

Fresnel lenses are pretty cool.

Thanks for your interest.

George Plhak

Lions Head, Ontario, Canada

Subscribe to:

Posts (Atom)