A recent example of the georgesworkshop do-it-yourself garden lamp that I have built here in the new workshop. (click any pic to enlarge)

This lamp is slightly brighter than the earlier ones since it looks after an important safety area where visitors step onto the deck from the grass. It uses C$1.50 LED chips bought on Ebay from China. Six chips can be installed in this lamp. I am using two. I am using slightly more DC current for more brightness but only use 4 watts total. I can adjust these lamps over a wide range of brightness by varying the DC power supply, a much wider range than with an AC dimmer. They don't go out all of a sudden but keep adjusting right down to zero.

I think these might qualify as dark sky lights because all the light is directed downward - none is wasted. This one uses about 4 watts of DC power at 18 volts from a recycled printer power supply. Nothing gets warm, the power supply and the LED chip are not working hard.

My lights are DC powered from an AC supply (they plug in). They are not yet solar powered but they could be. I would put the battery inside the house to keep it warm and the solar panel on the roof for better exposure. Where I want the light is not the best place to gather it in most cases and with more than a few lights, it pays to centralize the battery and panel. I plan these lights to be wired with good quality outdoor wiring into permanent locations but for now they are portable prototypes.

As in the examples last year, I've used plain 2x4 wood as the frame material. I did call this project "making a lamp from a 2x4". Of course, you can use any wood in any thickness or condition that appeals to you. These can be as skillfully and carefully made as you would like. This is a do-it-yourself (diy) project - feel free to customize. I will show you a framework that you can build on.

My lamp is made from the plain spruce 2x4 sold here in North America for building walls in houses. It is not very fancy but is cleanly cut and fastened with four deck screws that you can see in the top surface, pretty basic construction, but strong. While at the lumber yard, I did pick good straight 2x4s without excessive knots. I was able to cut them cleanly at 90 degrees on a saw. I pre-drilled the screw holes to prevent splitting.

The cost of the wood used in one of these lamps is about a dollar. The wood weathers nicely. After a year or two outside it turns grey and it will be solid in this climate for at least five years, maybe ten, even without a finish. For an outdoor lamp, I do feel that the standard 2x4 is a good material to consider.

I've continued with the U shaped frame construction. I have added a combination heat sink and reflector made of thin aluminum (roof flashing). The reflector shape keeps the block in place. The glass block is a commercial product bought at a home center. It acts as a light diffuser and a weather seal for the LEDs. I like the solid glass block appearance but is the most expensive part of this lamp, about $25. Other glass can be used as a diffuser as I show in some samples below.

I am building a number of these lamps for presents and give-aways to get feedback. I have made five this week. The last one took about an hour and a half construction time with about $5 worth of materials, other than the block.

I am using these lamps myself: three light the house back entrance and two are inside as table lamps.

If you have been reading about the project, you know that I had some trouble last year with one of the lamps whose led had failed in a strange way - it was flashing. This year, I am not using the Princess Auto LED described in that report but another which is less expensive and brighter. Hopefully more reliable! It was important to look at a number of sample LEDs to pick the best of what was available. The test bench helped with that.

These lamps use surplus "wall wart" power supplies to convert line power (110 VAC) into what the lamps need (about 9-10 volts DC). By matching each lamp with a suitable power supply, I can set the brightness in a range from downright frugal security light (about a watt used) to very bright, as much as commercial led bulbs using 10 watts but they run way cooler since they are more efficient. These lamps are safe if properly constructed. You can add your own creativity to the basic construction. You can use recycled material like the glass the wood and the power supply.

For this series of lamps, I've settled on a 10 watt LED bought on Ebay from China for about C$1.30ea for 10 with free delivery. They arrived in about a week. They are similar to the ones I showed you here. This is the response curve for these LEDs as measured at my test bench.

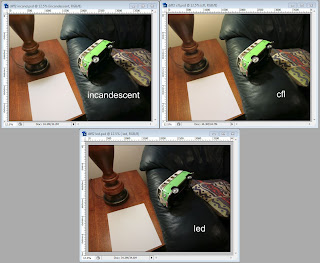

To create the graph, I am increasing the power to the LED on the x axis and measuring the light output on the y axis. I am actually increasing the voltage, measuring the current and multiplying the two to get the power (watts). You can see the complete spreadsheet here. You'll see that after about 10 watts, I don't get more light from the LED, just more heat. If I go higher still, I actually get less light. It's interesting that this is offered as a 9 volt to 12 volt LED. I don't think it would be a good idea to run this LED at 12 volts since it would get dangerously hot, enough to burn itself out or cause a physical burn if touched? But they are great at about 9 volts. They give a very pleasing warm white light efficiently with very little heat.

Here is another variation which uses an Ikea Neglinge candlestick holder, mounted upside down, for a great light diffuser. These clear heavy glass candlestick holders are available at IKEA stores for C$0.79. Some of the details of the construction of this prototype are shown in the insets (click to enlarge).

I have a video of one of these lamps being dis-assembled here at Vimeo that will give you a closer look.

Another family portrait

As always, your feedback is welcome and encourages me to continue working on this project. Thank you.

It is great to be able to make things in the new workshop and to show them to you.

George Plhak

Lion's Head

Ontario

Canada