Much is written about the benefits of shielded "dark sky" lighting. The main benefits are reduced light pollution, improved security and reduced energy use. You can read more about the dark sky movement at Wikipedia.

Shielded light fixtures focus light downward where it does the greatest good. No light is allowed upward into the night sky or over into a neighbor's property. Lower light levels produce less glare and save energy. Less glare makes for better security since it is easier to see intruders without being blinded by a bright, exposed light source.

Health benefits are also claimed, for humans and our animal friends. See Scotobiology.

I was challenged to make a shielded version of my Do It Yourself (DIY) garden lamp. My lamps already use very little power, adjustable from 1 to 10 watts yet produce a surprisingly bright field of illumination. Since the LED is mounted up inside the lamp, no vertical light escapes (light above the horizon) but because of the glass diffusers being exposed, some light does escape horizontally. I wanted to show a design that controlled the light in a manner consistent with the definition of a shielded lamp.

Construction

Continuing with my theme of using commonly available recycled materials where ever possible, I visited the local recycling store and purchased a rather used medium sized stainless steel mixing bowl with a flat bottom and a squat jelly jar. Total cost $1.25.

The jelly jar will provide protection for the LED and some light diffusion. The lid of the jar will be mounted on the flat in the bottom of the bowl so it was important that the jar lid diameter was less than the diameter of the flat part of the bowl.

It would have been better to use a spun aluminum bowl instead of the stainless steel because the bowl will also function as the heatsink for the LED. At lower power that is not really necessary and the steel will work well as a heatsink but at 10 watts and above in a hotter climate, the aluminum would be a better choice if you have that option. It seems that stainless steel bowls are most common although I do have some aluminum bowls from IKEA. I will check at IKEA on the next trip to see what they have available.

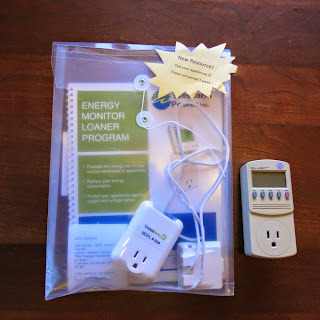

These are the basic parts less the LED and wire. The jelly jar is shown where it will be mounted, at the center of the bowl. The L-bracket is made of ordinary framing lumber. What I had at hand was some pressure treated 2x6 but I could have used pine, cedar or any wood of pretty much any thickness or width.

I cut one end of the support arm round to match the flat bottom of the bowl and you should be able to see the cross hair I marked to show where the center of the bowl will mount to the arm (click any picture for an enlarged view).

The arm is screwed to the upright with two deck screws. I pre-drilled smaller holes to help line the two pieces up and to help prevent splitting of the wood.

As with all my projects, even though this is a prototype, I smoothed the cut edges with a file and then some sandpaper to make for a more finished appearance. Generally I don't apply a finish. I prefer to let my outdoor lamps turn grey for a weathered natural look but you can finish yours in any way your like or leave them rough. You could use reclaimed wood or new. The cost of new wood and the two deck screws would be about $1.

I need the multiple holes I am going to drill through the jar lid and the bowl to line up precisely. First, I found the center of each and drilled one hole just slightly larger than a small bolt (I used a 4-40 or M2 bolt and nut) to fasten the jar and the bowl together temporarily. I then marked the location of the three holes that will ultimately hold the wood screws fastening the jar and bowl to the arm.

In this picture, I have inserted the same type of machine screw and nut in all four holes to check that they all line up.

I am going to take this apart after the holes are drilled. You can see that I marked ONE of the outer holes with a marker to distinguish it on both the lid and the bowl so that I can reassemble in the same orientation so everything stays lined up. The marker shows the front hole, the one that will be toward the front of the lamp.

In this picture, I have removed the center bolt and nuts, marked the locations of the mounting holes for the chip LED and I am drilling those holes with the jar lid and the bowl still screwed tightly together with the three outer bolts and nuts to ensure accuracy of the through holes for the LED.

Since the LED I am using relies on bolts at it's edge to hold it in place, these holes must be the most accurate of all. The LED must be firmly held to the jar lid to allow the heat it produces at higher power to be dissipated. If it cannot get rid of it's heat, it will overheat and fail. I will also coat the bottom of the LED with thermal grease and the corresponding area where the jar joins the bowl to help with heat dissipation.

One final, larger hole drilled through both the jar lid and the bowl will allow the wire to pass into the jar to be attached to the LED. I then remove the three screws, take the jar lid and the bowl apart and remove any burrs and chips from the drilling.

Reassembled in this view with the three bolts and nuts and the smaller bolts and nuts holding the LED in place. I have attached the wire to the LED with solder. I do not use connectors if possible on outdoor construction since I feel that a hard soldered connection is going to provide better reliability.

You will see that I have marked the negative wire (the one attached to the negative terminal of the LED) with a small piece of black heat shrink. I have also marked the other end of the same wire with another piece of heat shrink. Since the LED is a DC device, it must be hooked up in the correct orientation. The LED will not produce light if it is hooked up backwards.

In this view, I have the jar lid and bowl screwed to the arm. I have removed the three bolts and nuts, lined up the holes and attached the jar lid and bowl to the arm with three small wood screws through the same three holes.

In this side view, you can see a shallow channel I have cut in the arm to pass the wire along so that it comes out of the back of the arm. In a later version I will fill the channel with caulking to hold the wire in place.

I have pre-drilled holes in the upright piece of wood to make it easier to attach the lamp to a post on the deck.

A final step, before taking the lamp outside to installwas to take it over the electronics bench to attach power to make sure the lamp was wired correctly. It worked the first time! While at the bench, I checked the light pattern with and without the jar fitted.

Performance

The lamp gives a pleasing warm white illumination with a very sharp cutoff.

The lamp in the picture is mounted about 2.5 feet up a post at the side of the deck. At this height it brightly illuminates a circular area about nine feet in diameter. There is very little spill, as can be seen.

In this test, I am driving the LED at about 9 volts from a recycled 9 volt DC "wall wart" power supply from the recycling center.

The LED I am using is the "10 watt" LED chip described in this article. From the spreadsheet testing results I gave in this article, the LED should be running at about 3.2 watts at this voltage. This is about the mid-range for this LED chip. I could run it at 1 watt and still have very usable light or comfortably up to 10 watts for much brighter illumination.

The Lighting Research Center Rensselaer Polytechnic Institute, Troy, NY gives definitions for

Full Cutoff, Semicutoff and Noncutoff as well as the difference between full cutoff and fully shielded. Who knew that lighting could be so complex?

In order to properly classify my light, I will have to draw some circles on the ground and get out my lightmeter. I prepared this illustration based on the bowl I used from the recycling center. The cutoff angle would of course be different depending on the dimension of any paricular bowl that was used, but these are the angles for my prototype.

External pictures of the shielded garden lamp

Thank you for your interest in my work.

George Plhak

Lion's Head, Ontario, Canada