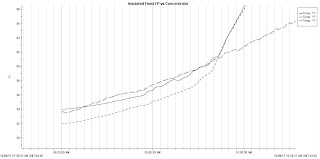

My previous experiments had used a bare mat black painted copper collector tube at the focus of a parabolic trough to capture heat. By introducing an insulator around the collector, it will be possible to reduce heat loss to the air which becomes severe during cold weather or when there is wind. Higher temperatures should also be possible.

Evacuated tube solar collectors (click pictures to enlarge) don't seem to be as common in North America but are in wide use elsewhere. The systems employ glass "thermos bottles" with a selective coating inside to trap the sun's heat. The interior contains a heat pipe. The heat pipe conducts heat to a metal bulb at the end which couples thermally into an insulated manifold through which circulates the heated fluid.

Here is an example of one such commercial system with an explanation of how it works

Fortunately due to high production volumes in China and India, the evacuated tubes are relatively inexpensive. I paid about $20 each for mine, a lot less than buying industrial glass tubing.

These type of commercial systems do not incorporate a large area concentrator. The heat captured in each tube is related to the area of the tube that faces the sun and maybe a bit on the back from the snow as a reflector in winter, some say. I felt that the usefulness of the tubes could be increased and less of them would be required if they were used at the focus of a concentrating reflector. The power into each tube could be increased, up to about 15x with my current concentrator. Would this be too much heat?

I had read that the heat pipes used are rated for a maximum of about 125 watts and I anticipated getting much more heat from the concentrator, perhaps 800 watts. Also, there was the difficulty of scaling up the manifold to the higher heat captured. So I had decided to remove the provided heat pipes and substitute a pipe loop into the interior of the evacuated tubes and to run my fluid directly through the evacuated tube.

Here I am beginning to remove the heat pipe from the evacuated tube. This one came out easily by simply pulling on the bulb. Others did not yield so easily as the heat pipe came out by itself and the glass fiber bung had to be picked out and then the aluminum heat coupler had to be pulled out with pliers. Different manufacturers use different designs for their heat pipes and mounting. This is only one example.

All evacuated tubes that I have seen are open at only one end. So it is necessary for the collector pipe to make a sharp bend at the bottom of the evacuated tube. The inside ID of the evacuated tubes that I am using is 43 mm. Here I have tried to create a bend to fit this diameter in 3/8" OD soft copper refrigeration line using a pipe bender. You can see that the tubing has crushed beyond usability. I had to find another way.

Commercial 90 degree elbows are just a bit too long so it was necessary to trim about half of one side of each of these elbows to create a 180 degree bend that would fit down the inside of the evacuated tube.

This is the final soldered result. I used silver solder at the shortened middle joint to give it a bit more strength.

The 3/8" copper tubing came on a roll. Creating more or less straight sections was an adventure in itself but I eventually, by hand and sighting by eye, had two more or less straight sections which were soldered into the 180 degree elbow. Next time, I will see if I can buy the 3/8" tubing in straight sections.

In my reading about people's experiments with evacuated tubes and seeing the construction of the commercial evacuated tube, I decided that it would be an advantage to have some additional surface area and heat conduction material inside the tube. I decided to use a copper mesh material over the copper tubes. I could have used, as others have, copper pot scrubbers but I had this

Lee Valley Copper Blocker material at hand. It is pure copper (not sure what the copper pot scrubbers are really made from) and it is formed as a sleeve, so it is easy to slide over the copper tubes.

Because I was going to push the copper tubes and the mesh down into the evacuated tube, I needed to fasten the mesh to the copper tubes so the mesh would not bunch up. The 180 degree elbow was only about 1.5mm smaller than the inside of the evacuated tube so the mesh could not be in that space. Here is what I ended up with. A couple turns of bare copper wire holds the mesh (bunched up at the end with a couple folds) to the 180 degree elbow. A dab of epoxy holds the wire loops in place so they don't slide around on the elbow. This assembly is ready to be inserted.

The fiberglas bung that came with the evacuated tube was crumbly and only had one hole so I needed a way to seal the open end of the tube with another material. Using fiberglas pipe wrap, I wound a small tight roll, placed it between the two pipes and then continued to wind around the pipes to create a fairly respectable bung just slightly larger than the ID of the evacuated tube. The picture at the top of this post shows the final seating of the bung, half of which disappears down beneath the selective coating. You can see the compression fittings that I added to the copper tube to allow connection to the system.

The evacuated tube was mounted in the solar test jig in the conventional manner of my concentrator design. Slightly enlarged holes in the hangers allows the reflector to simply hang from the evacuated tube (the reflector only weighs about 5 pounds) and to pivot around it. Small saddles were made with a semicircular opening just slightly larger than the evacuated tube OD for the tube to sit on and it is held in place with straps with padding strips on the underside and gentle pressure from the two mounting screws. The white cylinder is a 3" PVC pipe joiner which functions simply as a spacer, to keep the reflector from sliding down to the frame.

The evacuated tube collector is finished and ready for testing.

Index - Comparing concentrator to flat plate solar collector